MITEE-BITE POWER-GRIP

POWER-GRIP is a heat-activated wax-based compound, excelent for holding smooth flat parts, optical and quartz components and jewelry related items. - Available as:

- Power-Coil with a paper carrier foil for holding

smooth, flat parts. - Super-Coil with a mesh carrier foil for higher

holding forces for holding irregular shaped parts. - Stick, which can be used in shallow cavities

for holding concave, convex and flimsy parts.

POWER-GRIP suits for steel, non-ferrous metals, glas, wood, most plastics and a lot of other materials.

Depending on the texture and the size of the contact area the holding force is 30 - 200 N/cm².

POWER-GRIP is non-toxic and can be removed free of residues.

| Art. No. | Content | |

|---|---|---|

| 10240 | 1 Power-Coil | 1500 x 300 mm |

| 10245 | 1 Power-Coil | 7600 x 300 mm |

| 10250 | 1 Super-Coil | 1500 x 300 mm |

| 10252 | 1 Super-Coil | 7600 x 300 mm |

| 10230 | 1 Stick | 65 Gramm |

| 10235 | 3 Sticks | 195 Gramm |

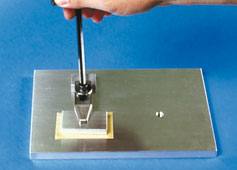

It's as simple to use POWER-GRIP

Step 1

Take a sheet of PowerGrip leaving a 6 mm border on all sides or melt stick on warm subplate.

Step 2

Press your working piece slightly on its support. Over large thin workpieces use a top plate for even pressure.

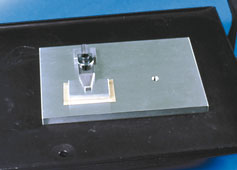

Step 3

Heat to approx. 85°- 95°C.

Place a separate piece of Power-Grip paper on part: temperature is correct when piece is melted.

Step 4

Displace workpiece from heat. Use air or water to cool, being careful to prevent water from going between subplate and workpiece while hot.

Step 5

Now the part is ready to machine. If necessary use coolant to avoid heating of Power-Grip. To remove part after machining, reheat to between 80°- 95°C.